Onshore Powersupply for tankers

As part of an innovative plan to provide shoreside power for tankers berthed at the Energy Terminal, the Gothenburg Port Authority has created a completely new and unique concept that makes the entire system safe, environmentally friendly, and cost-effective. The project – named Green Cable – is being run in association with shipping companies on the island of Donsö, as well as national and European ports, classification societies, local oil companies, and the Swedish Transport Agency.

The aim is to set a new global standard for shoreside power for tankers berthed in a hazardous environment.

The environmental benefit from supplying power to tankers is a reduction of 1 200 tonnes of carbon dioxide a year when vessels use green electricity instead of marine diesel.

A new standard for tankers

The greatest challenge is to ensure that tankers that are scheduled to be built and the shoreside power connectors that are fitted adhere to a common standard applied at all ports. A further challenge is the ever-present risk of an explosion when the vessel is berthed at an energy terminal as the combustible and flammable products being pumped could easily be ignited by a spark from the electrical equipment. These challenges have become an intrinsic part of the planning process.

When tankers are at sea their classification normally specifies that a power supply point can only be located aft of the bridge. Vessel designers have used this as a starting point when designing new vessels fitted with shoreside power connectors. However, this classification does not apply when the tanker arrives at an energy terminal. In the majority of cases it is superseded by the port’s classification, which means the entire vessel is deemed to be an explosive atmosphere, including the aft.

The downside of having a power supply point at the aft is that the length of a vessel can vary considerably. In many cases vessels are more than 150 metres long and the quays are considerably shorter. Locating a power connector at the aft would require ports to build connection cranes at the quayside to reach the connector. Likewise, extremely long cables would be required together with complicated and expensive cranes to lift the cables.

The new standard proposed by the Port of Gothenburg is for all tankers to have their loading crane midships, which would be the optimal solution for lifting the power cable on board.

As a result, the length of the vessel would no longer be an issue and whether she moors starboard or port side is irrelevant. This new standard will also result in substantial cost savings at each berth.

Unique shoreside power solution

Volatile and highly combustible gases present during loading and discharge of hazardous products and the risk of sparks during connection is a dangerous combination. This has been resolved by working with overpressure in the quayside spaces where the cable is housed and in onboard spaces where the cable is connected. This solution will shut out any explosive gases, making the whole facility safe.

-1 200 TONNES CO₂

The benefit from supplying power to tankers is a reduction of 1 200 tonnes of CO₂ a year when vessels use green electricity instead of marine diesel.

-1 200 TONNES CO₂

The benefit from supplying power to tankers is a reduction of 1 200 tonnes of CO₂ a year when vessels use green electricity instead of marine diesel.

0%

The benefit from supplying power to tankers is a reduction of 1 200 tonnes of CO₂ a year when vessels use green electricity instead of marine diesel.

0%

The benefit from supplying power to tankers is a reduction of 1 200 tonnes of CO₂ a year when vessels use green electricity instead of marine diesel.

Jörgen Wrennfors

Senior Production and Business and Development

+46 70 218 93 81

jorgen.wrennfors@portgot.se

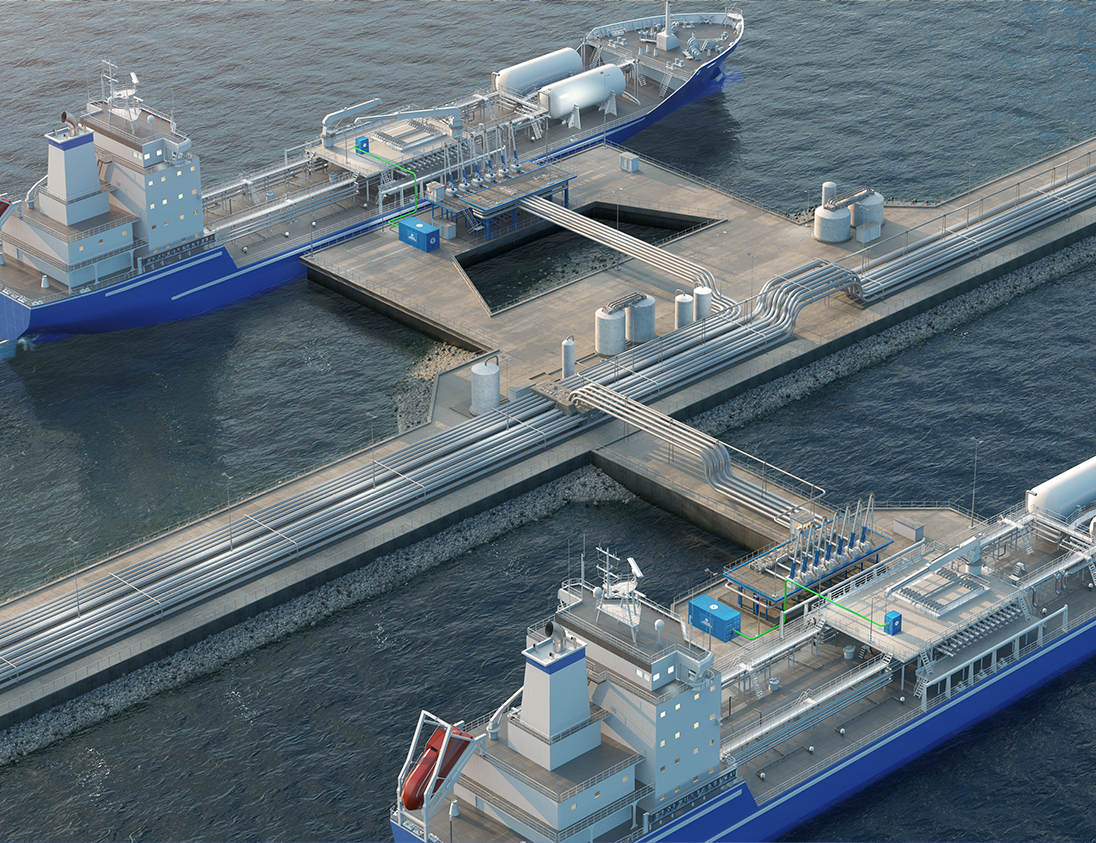

Rendered overall view.

Rendered close-up view.

Fact file

-

Environmental gain: 1 200 tonnes of CO2 will be saved each year. Green power will be used instead of marine diesel.

-

The new facility at the Energy Terminal is designed to be a permanent feature in an explosive atmosphere. Safety equipment will be supplied as standard along with the power supply connector.

-

Safety is guaranteed thanks to a technical solution with overpressure in spaces in which electrical equipment is housed.

-

The Donsö-based shipping companies Furutank, Donsötank, Tärntank, Ektank and Veritas Tanker, as well as Tarbit Tanker on the island of Tjörn are all

part of the project. They have already ordered vessels on which the new power supply solution has been incorporated. The first pre-prepared vessels were

delivered in 2021, and the first vessels that are completely ready for shoreside power connection delivered in February 2022. -

Funding: The system will be partially funded with SEK 10.7 million from the government through the Climate Investment Support Programme.

-

Project implementation: 2022/2023.

-

Completion: During Q1 2024 the first tanker will be connected to a green shoreside power supply at the Energy Terminal.

-

The Gothenburg Port Authority is currently investing around SEK 600 million in carbon mitigation measures in a concerted effort to achieve the port’s climate goal by 2030.

System design

-

Power supply: up to 2 MW per jetty.

-

Supply Voltage: 6.6 kW.

-

Grid frequency: 50 Hz.

-

Cable management system: Shore based cable, handling with onboard crane.

-

Plug and socket system: Cavotec PC6.

-

Power intake position: midship in manifolder area,flexible position for starboard or portside handling.

-

ATEX: design for permanent risks in hazardous area zone 1.

-

Compartment design: at ship, over pressured by nitrogen to reduce oxygen level below 21 % at shore side, CMS over pressured system by air from safe area.

Onshore Power Supply

The Port of Gothenburg has extensive experience with shoreside connections and ar actively working to ensure that more ships turn off their engines at the quayside and use shore power instead.

The RoRo-terminal at the Älvsborg Harbour is the first onshore power supply to be established at the Port of Gothenburg. It was set up in 2000 at berths 700 and 712. Since 2011, all of Stena Line’s ferries have been shutting down their engines and instead using the Onshore Power Supply